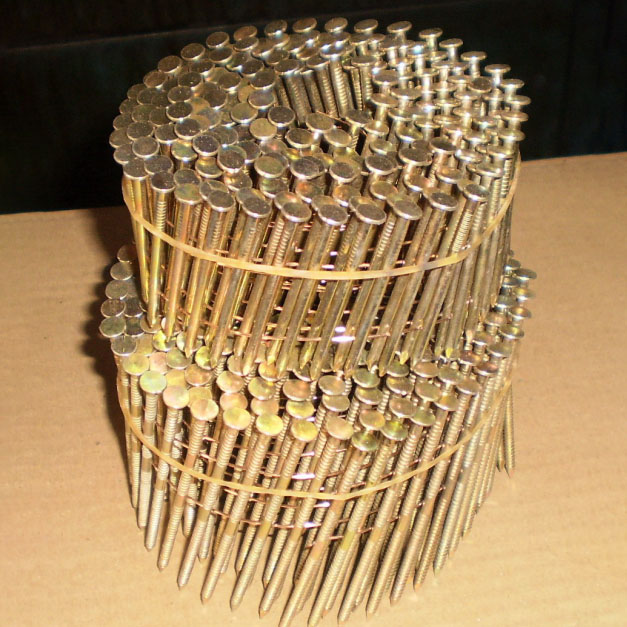

Hot-Dip galvanized coil nails sell well

The previous brushed process adopted an ordinary cold pull -up process. After the silk nails were pulled out, it was necessary to polish through the wood chips. Due to the use of wood chips, it fell in the air, resulting in severe air particles pollution. The paint of the paint should wait more than half an hour in the air to dry. Although it isolate and use active carbon for adsorption, it will still cause a certain irritating odor, which is not conducive to the health of the staff.

The purpose of the invention is to overcome the lack of existing technology, providing a production process with simple craftsmanship, high production efficiency, good product quality, and small environmental pollution. In order to solve the above technical problems, the production process of a rolling nail described in the present invention includes steps

(A) Prepare the metal materials required for nails.

(B) Remove the oxidative skin to clean the surface of the metal material, and use the lubricant to cool the cleaning steel pull; it can reduce artificial losses and reduce the environmental pollution. Suitable for industrial production.

Angle: 15 degree flat or 16 degree conical, 11 degree, 0 degree.

Diameter: 0.083" 0.092" 0.099" 0.113" 0.120" 0.131" 0.148".

Length: 25mm-130mm.

Shanks: smooth, ring, screw.

Point: diamond, chisel, blunt.

Finish: bright, E.Galv. M.Galv. H.D Galv. 304 316 stainless steel.