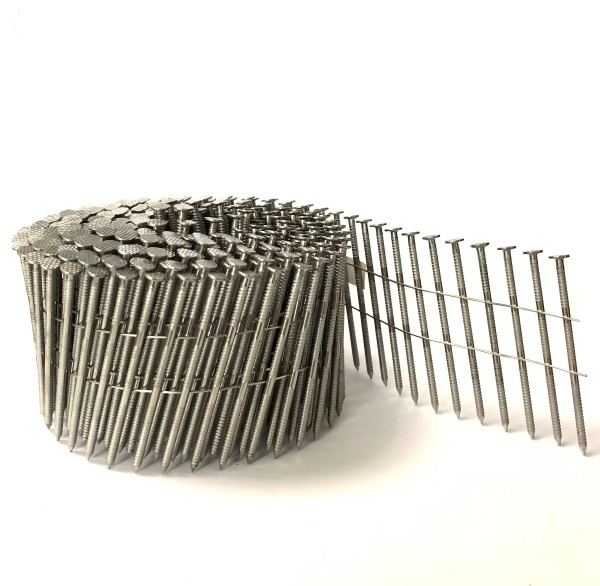

As global construction and manufacturing industries continue to evolve, the demand for stainless steel coil nails has been on the rise. These specialized fasteners offer superior durability, corrosion resistance, and strength, making them the preferred choice in challenging environments such as coastal construction, outdoor structures, and high-humidity applications.

Market Growth and Driving Factors

The stainless steel coil nails market has witnessed steady growth, driven by several key factors:

Corrosion Resistance in Harsh Environments

Unlike traditional galvanized nails, stainless steel coil nails provide long-lasting performance, even in extreme weather conditions. This makes them essential in marine projects, decking, roofing, and exterior siding applications.

Increased Use in High-End Construction

With the rising demand for high-quality and sustainable building materials, stainless steel nails have gained traction in premium housing, commercial infrastructure, and green building projects.

Stronger Regulations on Rust-Free Fastening

Many industries now mandate the use of rust-resistant fasteners to ensure structural integrity and longevity. Stainless steel nails meet these stringent quality requirements, reducing long-term maintenance costs.

Expanding Applications in the Pallet & Packaging Industry

In the logistics sector, stainless steel coil nails are increasingly used in pallet manufacturing, especially for export packaging where rust-free nails are crucial to meeting international standards.

Technological Advancements in Stainless Steel Coil Nail Production

Recent innovations in fastener manufacturing technology have significantly improved the production efficiency and quality of stainless steel coil nails.

Advanced Wire Drawing Techniques: High-precision wire drawing ensures uniform shank diameter, enhancing the overall performance of the nails.

Automated Coil Nail Assembly: Modern manufacturing lines with robotic automation improve consistency and reduce defects.

Superior Heat Treatment Processes: Optimized heat treatment enhances the nail’s tensile strength and durability.

Future Outlook

As the demand for sustainable and corrosion-resistant fastening solutions continues to grow, stainless steel coil nails are expected to play a crucial role in the future of construction and manufacturing. Companies investing in high-quality stainless steel fasteners will gain a competitive edge, particularly in global markets where environmental and quality standards are becoming increasingly stringent.

Conclusion

Stainless steel coil nails are no longer just an alternative to traditional nails—they are a necessity for industries that demand durability, corrosion resistance, and long-term performance. With advancing technology and increasing market demand, manufacturers and suppliers should focus on delivering high-quality, certified stainless steel fasteners to meet the evolving industry needs.

Post time: Feb-26-2025