Stainless steel coil nails are mainly made from 304 and 316 stainless steel, both known for their excellent corrosion resistance and mechanical properties.

- 304 Stainless Steel (18% Chromium + 8% Nickel): Suitable for general outdoor applications like wooden houses, fences, and roofing, offering good resistance to moisture and rain. However, it may still corrode in highly saline or chemically aggressive environments.

- 316 Stainless Steel (18% Chromium + 10% Nickel + 2% Molybdenum): The addition of molybdenum (Mo) significantly improves resistance to chloride corrosion, making it ideal for marine environments, chemical plants, bridges, and other high-corrosion areas.

For extreme environments such as food processing plants or medical equipment, higher-grade stainless steels like 410 stainless steel (martensitic type, higher hardness but lower corrosion resistance) may be required.

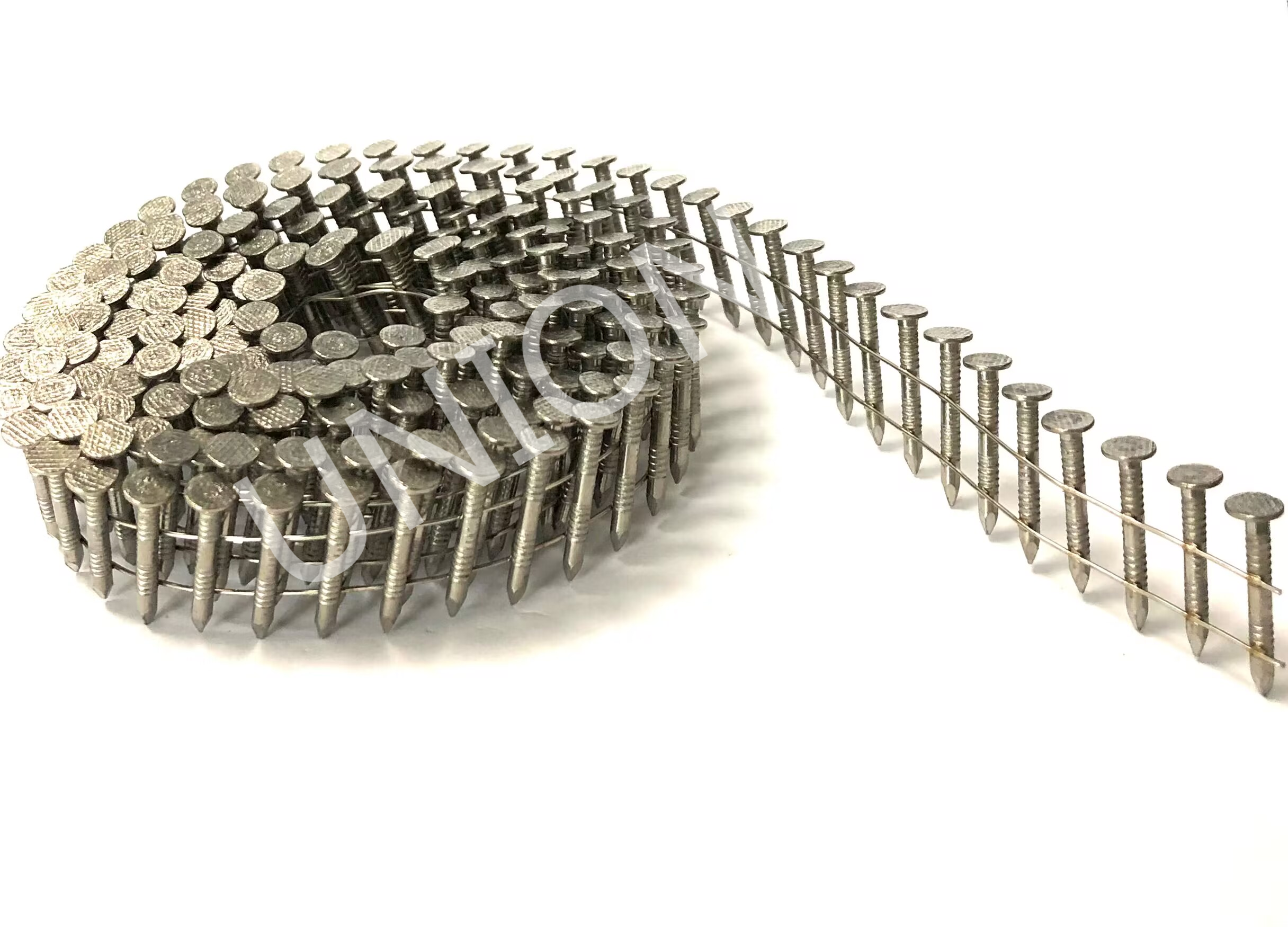

2. Welding Technology of Stainless Steel Coil Nails

The welding process plays a crucial role in ensuring the durability and stability of stainless steel coil nails. High-quality nails use high-frequency resistance welding, ensuring uniform and strong weld points. Poor-quality welding may lead to nail breakage or detachment, compromising construction safety.

3. Applications and Key Advantages

Stainless steel coil nails are widely used in the following fields due to their excellent corrosion resistance and high strength:

- Wood Construction: Suitable for wooden house building, timber framing, and roofing installation, ensuring secure connections and enhancing the durability of structures.

- Outdoor Landscaping Projects: Used for garden fences, decks, and boardwalks, providing long-term resistance to weather exposure and preventing rust or loosening caused by humidity changes.

- Coastal Protection & Dock Construction: In high-salt environments, stainless steel coil nails effectively prevent corrosion, ensuring the safety and longevity of wooden structures, railings, and decking.

- Bridges & Infrastructure: Ideal for coastal and humid regions, ensuring the stability of bridges, guardrails, and wooden platforms, while reducing maintenance costs.

- High-End Interior & Furniture Applications: In premium furniture manufacturing and wood panel installations, stainless steel coil nails not only offer superior corrosion resistance but also maintain the aesthetic quality of joints, preventing rust from affecting the overall appearance.

4. UNION’s Products & Services

As a professional hardware supplier, UNION provides high-quality stainless steel coil nails with:

✅ Custom nail sizes, angles, and head specifications

✅ Bulk supply with stable delivery to support your business growth

Post time: Feb-19-2025