Introduction to Plastic Coil Nails

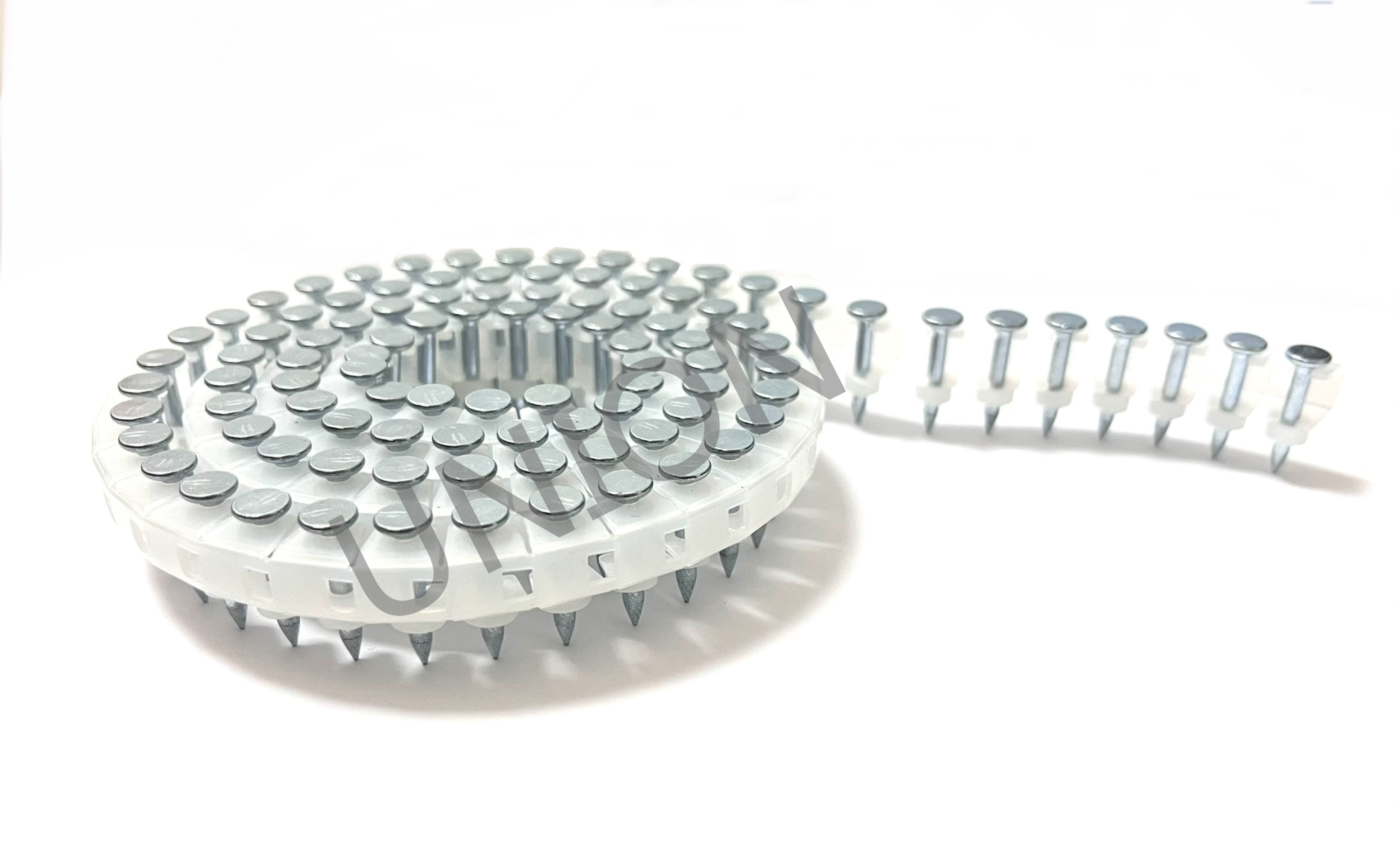

Plastic coil nails are a type of fastener widely used in the construction and woodworking industries. Their key feature is the plastic strip that holds the nails together in a coiled form. Compared to loose nails, plastic coil nails offer easier installation, increased efficiency, and reduced material waste. They are commonly used in large-scale automated nailing tasks such as pallet manufacturing, furniture assembly, fencing, and wooden structures like sheds and houses.

Advantages of Plastic Coil Nails

One of the main advantages of plastic coil nails is their excellent organization and fast operational speed. The nails are arranged in a coil connected by plastic strips, allowing workers to use nail guns for continuous nailing without frequent reloading, which significantly boosts productivity. The plastic strip material is durable and flexible, reducing the risk of breakage or deformation during use, ensuring accurate nail placement. Additionally, plastic coil nails offer better rust resistance compared to other types of coil nails, as the plastic strip does not corrode like metal ones.

Applications

Plastic coil nails are widely used in industries where large amounts of continuous nailing are required. They are particularly common in pallet manufacturing, where they securely fasten wooden boards together. In wooden structures like fences, roofs, and walls, plastic coil nails help save time during construction due to their efficient installation process. Furthermore, plastic coil nails perform exceptionally well in outdoor structures such as sheds and fences, especially in humid or rainy environments, where their rust-resistant qualities greatly enhance durability.

Development Trends of Plastic Coil Nails

With the increasing automation of construction and the growing demand for efficiency, the use of plastic coil nails is becoming more widespread. Many manufacturers are gradually shifting to plastic coil nails due to their environmental and durability advantages. As material science advances, the quality and stability of plastic strips continue to improve, allowing them to meet more complex construction needs. In the future, plastic coil nails are expected to expand their presence in global markets, becoming a preferred choice for various construction projects.

Post time: Dec-12-2024