At present, the main types of nail row production equipment are: paper strip nail , plastic strip nail , steel nail row, etc., the shape of a single nail is divided into F, T, U and so on. According to its production process, the row nails can be divided into two categories: one is paper row nails, plastic row nails, straight row nails; Another type is steel row nails. Its characteristics are as follows: paper row nails, plastic row nails: Because the use of such row nails on the strength, hardness requirements will not be as high as cement nails, so in the production process saves a lot of processes, for our country is currently able to achieve automated production, and the technology is more mature. After investigation, the material used for this kind of row nails is mainly carbon steel. The general production process is as follows: the round wire is straightened and flattened by the flattening machine, and is set on a certain number of spool, and is glued and dried by the gluing machine to make wire belt, and the wire belt is sent into the forming machine for cutting, forming and heading, so as to complete the entire production procedure. Steel row nails is one of the many row nails series, because of its high strength, high hardness, can be nailed into concrete and other relatively hard materials, steel row nails characteristics:

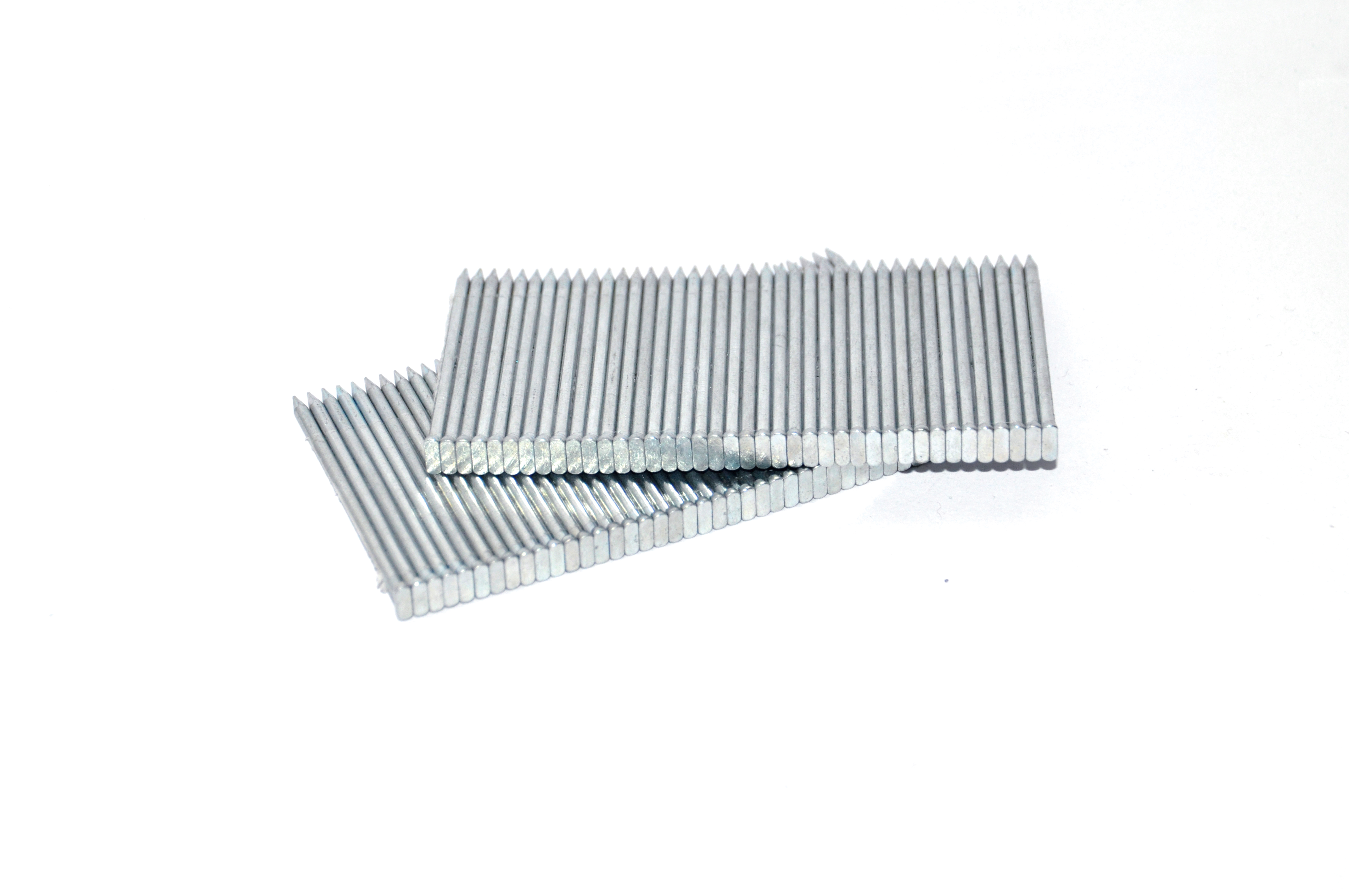

a. The diameter of a single steel nail is 2.2mm, and the length is 18mm, 26mm, 38mm, 46mm, 50mm, 64mm and other different specifications.

b. Steel nails must be 40 steel nails in a row, and the top and sides must be flat without warping.

c. The nail row must have a certain rigidity and strength: hold one end, and the other end must not sink and break.

d. The nails must be in close contact with each other, and there must be no gap. The glue is evenly coated, no tumors and bubbles, and the glue boundary is limited to 10mm below the nail head.

Steel nail is a disk round wire as the raw material, the wire drawing machine several times to the wire diameter required by the steel nail row, by the nailing machine to produce specifications of steel nails, quenched by the heat treatment furnace, and then polished by the polishing machine, and then galvanized equipment for electroplating, and finally by manual gluing, the steel nails into a row of qualified products.

The difference between steel row nails and paper, plastic, straight and other row nails

Steel row nails are very different from others. First of all, their applications are different; Secondly, the materials, production equipment and production process used in the two types of nails are very different. So far, the steel nail production process can not be automated, can only produce a single steel nail, and then manually complete the nail; The production of paper, plastic, straight and other ordinary row nails is basically automated, and the efficiency is relatively high.

![~[6PHCON20$7]]XS69]TSRF](http://www.hbunisen.com/uploads/6PHCON207XS69TSRF.png)

Post time: Jan-11-2024