Other machines

-

Blocks Multi Rip Saw

Blocks Multi Rip Saw is suitable for cutting chip pallets, solid wood, multi-layer wood, it dominates the wood panel processing equipment, this machine has the characteristics of stable operation, efficient production, safe operation and easy maintenance.

This Blocks Multi Rip Saw is simple and easy to operate, the machine has less dust and very good dust collection effect when cutting wood blocks.

-

Rotary type dryer

The special dryer for wood chips is designed and manufactured for drying sawdust, small wood chips and wood veneer. It is characterized by large drying output, remarkable energy-saving effect and low maintenance. The main working principle is: wood chips enter into the rotary drum by the blowing pipe and the rotary cylinder body together, the material in the cylinder boiling fluidization, hot air and the material fully touch, complete drying.

-

Mixer

Mobile small mixer turn light and handy, using single-phase reducer motor, easy to use electricity, as long as there is a lighting power supply of the pen can be plugged in to use. The mixing barrel is made of high-strength rust-free steel plate, so you don’t have to worry about rusting and contaminating the feed caused by mixing fermented feed. Combined with the special structure design of the stirring knife, so that the processing of raw materials in the barrel tumbling speed, stirring to achieve a complete dead-end, completely solve the traditional mixer barrel bottom of the existence of dead-end mixing uneven problem, high mixing uniformity, in the mixer to add preventive drugs and feed additives without worrying about mixing uneven medicine. Although the mixer structure is small, but the installation of the reducer motor mixing strength is absolutely strong, mixing efficient and powerful.

-

Pipes Dryer

The so-called airflow drying refers to the wet sawdust in the form of powder and granule, which is continuously added into the drying tube by screw conveyor. In the high-speed hot air conveying and dispersion, so that the moisture in the wet material evaporation, get powder or granular dry product process. It is mainly composed of air heater, feeder, airflow drying tube, cyclone separator, fan and so on.

-

Wood Block Presser

Wood Block Presser mainly uses shavings, wood chips and other waste materials, by mixing with the glue ratio, through drying, gluing, hot press heating and pressure to produce shavings, wood chips foot pier, the surface is smooth and smooth, good waterproof (soak water 48 hours without cracking, wind scraping and sun exposure without cracking). Equipment structure is simple, easy to operate, the production of wood pads clean and environmentally friendly, broad market prospects, in line with national industrial development policy. It is necessary to pay attention to: you need to wear goggles when operating to ensure safety.

-

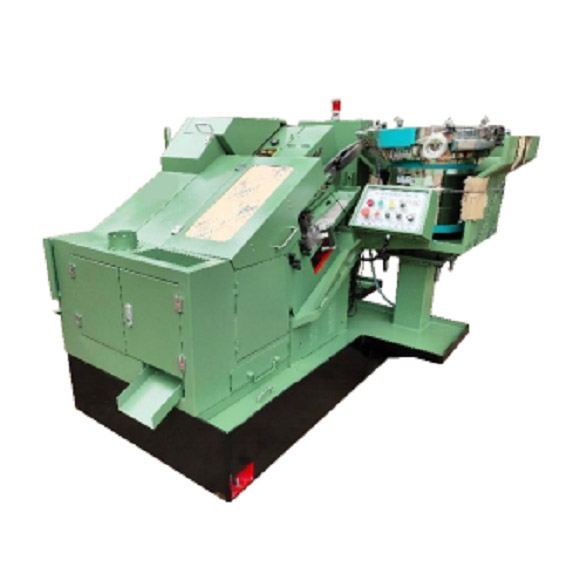

Self Drilling Screw Thread Rolling Machine

Efficient Forming: The screw thread rolling machine significantly reduces production cost by direct pressing method without cutting process and producing no waste. The high productivity of the machine ensures uniformity of thread finish and accuracy.

Enhanced Strength: Compared with traditional cutting process, thread rolling process produces threads with higher strength and more durable finished products, which are suitable for a variety of industrial applications.

-

Self Drilling Screw Point Forming Machine

The tail of the drill tail screw is in the shape of a drill tail or a pointed tail. It does not need to drill holes on the workpiece first, and can directly drill, tap, and lock on the setting material and base material. Compared with ordinary screws, the drill tail screw High tenacity and retention force, it will not loose after a long time of combination, easy and safe to use, drilling and tapping can be completed in one operation, saving time, labor and labor. Drilling screws are mainly used to fix metal plates such as steel plate fasteners, generally used for locking metal plates and non-metallic plates, such as for directly fixing silicon-calcium boards, gypsum boards and various wood boards on metal plates. Drilling screws with reasonable design and structure can make the metal plate and the mating plate tightly locked, avoiding damage and scratches of the mating plate, and are easy to install.

-

USGT 6-12 NC Steel Bar Straightening Cutting Machine

Main used to cut round bar straightening and cutting, usage as below:

For cold rolled ribbed steel bars for construction, hot rolled steel, cold rolled smooth surface round bar, hot rolled rebar, round bar, etc. (to change the straighten barrel use 8wheel).

-

UST 4-10 NC Steel Bar Straightening Cutting Machine

1. Straightening and cutting steel bar dia: ¢8-¢10mm

2. Cutting length: 0.75m-6m3. speed: 50m/min

3. Output (each 8hours): ¢6(4-5tons); ¢8(6-8tons); ¢10(8-10tons)

4. Input batches simultaneously: 1-20batches

5. Single batch cut pieces: 1-9999. Length tolerance: ±3-4mm

6. Power: 50HZ

7. CNC box power: ≤14w

8. Volume: 2500×700×1300mm

-

Full Automation and Low Consumption Clip Nail Making Machine

This machine is developed by our company based on the production process of nail clipping machine equipment and supporting equipment.It helps the production process develop from pure manual operation to full automation.It’s highly efficient and can help you reduce cost of labor.