Products

-

Grassland Mesh Machine

Grassland Mesh Machine is a wrap-around fence net, which is characterized by being difficult to pull apart, full of elasticity, and the secondary net is not easy to rust.

-

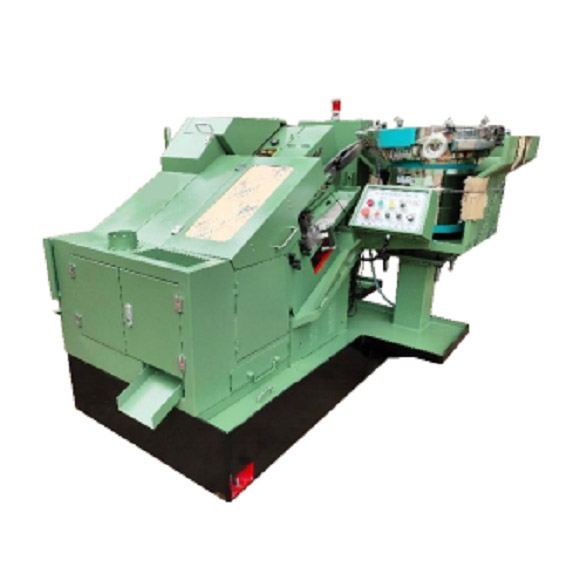

Thread rolling machine

The working principle of thread rolling: it is two identical pieces, the thread rolling surface has the same tooth shape as the thread shape of the bolt thread and the same helix angle. When the thread rolling plates move with each other, the bolt blank between the two thread rolling plates is rubbed out of the thread . The thread rolling plate goes back and forth one bolt thread at a time to complete the processing, and the speed is quite high.

-

Self Drilling Screw Thread Rolling Machine

Efficient Forming: The screw thread rolling machine significantly reduces production cost by direct pressing method without cutting process and producing no waste. The high productivity of the machine ensures uniformity of thread finish and accuracy.

Enhanced Strength: Compared with traditional cutting process, thread rolling process produces threads with higher strength and more durable finished products, which are suitable for a variety of industrial applications.

-

Self Drilling Screw Point Forming Machine

The tail of the drill tail screw is in the shape of a drill tail or a pointed tail. It does not need to drill holes on the workpiece first, and can directly drill, tap, and lock on the setting material and base material. Compared with ordinary screws, the drill tail screw High tenacity and retention force, it will not loose after a long time of combination, easy and safe to use, drilling and tapping can be completed in one operation, saving time, labor and labor. Drilling screws are mainly used to fix metal plates such as steel plate fasteners, generally used for locking metal plates and non-metallic plates, such as for directly fixing silicon-calcium boards, gypsum boards and various wood boards on metal plates. Drilling screws with reasonable design and structure can make the metal plate and the mating plate tightly locked, avoiding damage and scratches of the mating plate, and are easy to install.

-

Thread Rolling Machine/ring shanker machine

The high-speed screw rolling machine produced by our company is researched and manufactured according to the principle of American imported machine, adopts main shaft and variable speed integration of cabinet, the machine oil in cabinet is in circulation cooling, has the advantages of high accuracy, high output, stable quality, durable in use and convenient operation etc. occupies the leading place in similar products in our company.

This machine matches with all kinds of special molds, can produces all kinds of abnormal-shape nails, mainly used in new-type nails of threaded nails and ring shank nails etc.

-

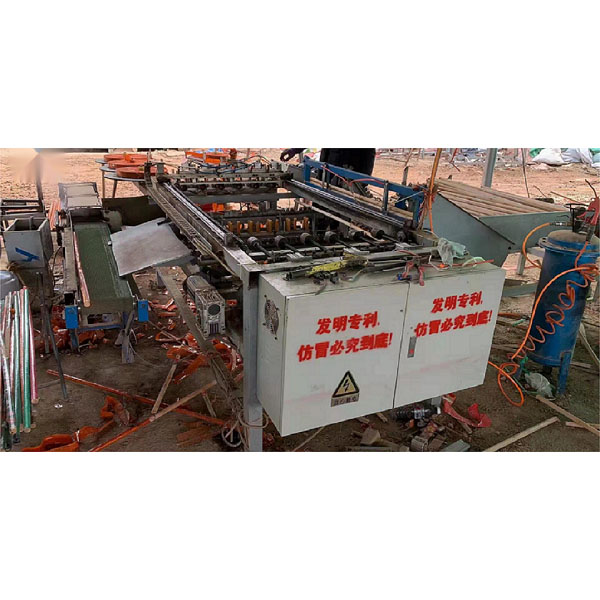

USGT 6-12 NC Steel Bar Straightening Cutting Machine

Main used to cut round bar straightening and cutting, usage as below:

For cold rolled ribbed steel bars for construction, hot rolled steel, cold rolled smooth surface round bar, hot rolled rebar, round bar, etc. (to change the straighten barrel use 8wheel).

-

UST 4-10 NC Steel Bar Straightening Cutting Machine

1. Straightening and cutting steel bar dia: ¢8-¢10mm

2. Cutting length: 0.75m-6m3. speed: 50m/min

3. Output (each 8hours): ¢6(4-5tons); ¢8(6-8tons); ¢10(8-10tons)

4. Input batches simultaneously: 1-20batches

5. Single batch cut pieces: 1-9999. Length tolerance: ±3-4mm

6. Power: 50HZ

7. CNC box power: ≤14w

8. Volume: 2500×700×1300mm

-

Broom handle PVC coating machine

The broom handle PVC coating machine mainly used for producing the wooden broom with PVC coated, and equipped with automatic discharging conveyor. Our machine can process 6 pcs broom handles at one time. The advanced U shape heating technology assures that the brooms are heated evenly.

The machine is mainly used for film sealing, cutting and packaging of broom handle. Put the rod that needs to be packaged into the push tray and push it in manually, then seal and cut. The suitable packaging material for this machine is PE film, which greatly saves labor costs compared with traditional manual lamination.

The laminating machine uses heat shrinkage to firmly cover the PE bag on the mop rod, so that the mop has a perfect packaging effect.

-

Full Automation and Low Consumption Clip Nail Making Machine

This machine is developed by our company based on the production process of nail clipping machine equipment and supporting equipment.It helps the production process develop from pure manual operation to full automation.It’s highly efficient and can help you reduce cost of labor.