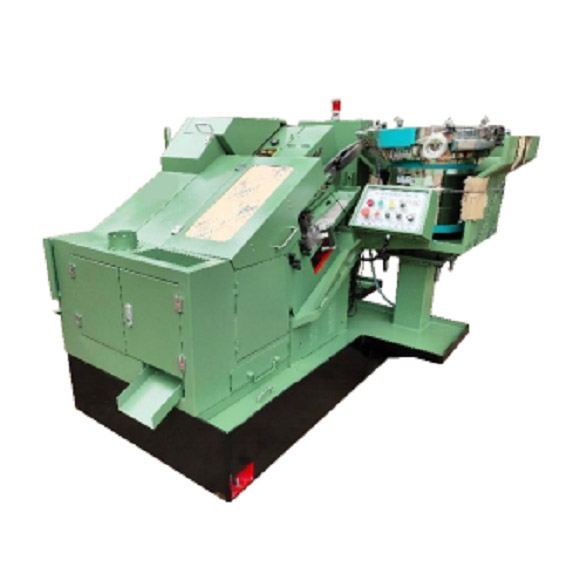

Self Drilling Screw Heading Machine

Detail

Our screw heading machine is a kind of cold heading equipment specialised in the production of screws, dedicated to the metal processing of screw basic forming. It is characterised by high flexibility and easy length adjustment, especially suitable for small batch production or sample making.

Characteristics of the equipment

Flexible production: The flexible operation and easy length adjustment of the screw heading machine can be quickly adapted to different production needs, especially suitable for small batch production and sample making.

Efficient operation: the output and quality of the machine is directly related to the skills of the operator, trained operators can utilise the full potential of the machine to produce high quality screws.

Multi-functional forming: Screw forming consists of two functions: screw form forming and thread forming. The screw shape forming machine is a screw heading machine, using cold heading technology, and the thread forming machine is a thread rolling machine, using extrusion technology. These two types of forming guarantee better surface quality and higher dimensional accuracy.

High quality machining: The screw heading machine with cold heading process ensures the surface quality and dimensional accuracy of the screw during the machining process. At the same time, due to the effect of cold hardening, the deformation needs to be controlled within a reasonable range to reduce material cracking.

| Model | Max.Cutdiameter | Max.BlankLengt | Stroke | Output rate | MainDie Diameter | Cut-offDie Dia | PunchDie (1st) | PunchDie (2nd) | Size of scissors plate | Body Motor Power | L*W*H | Weight |

| unit | mm | mm | mm | Pcs/ min | mm | mm | mm | mm | mm | KW | mm | KG |

| US-5 Semi-Closed |

3 |

25 |

38 |

140-180 |

20*35 |

13.5*25.5 |

18*38.5 |

18*45 |

|

1.1 |

1310x770x1060 |

700 |

| US-5A Half-Hollow |

3 |

20 |

38 |

100-120 |

20 |

13.5 |

18 |

18 |

|

1.1 |

1450x770x1060 |

750 |

| US-5G Semi-Closed |

3 |

30 |

50 |

140-220 |

20*50 |

13.5*30 |

18*45 |

18*55 |

|

1.5 |

1450*840*1080 |

900 |

| US-5G Totally-Enclosed |

3 |

30 |

50 |

140-220 |

20*50 |

13.5*30 |

18*45 |

18*55 |

|

1.5 |

1440*830*1080 |

950 |

| US-10B Semi-Closed |

4 |

40 |

62 |

160-180 |

30*55 |

15 |

25 |

25 |

|

2.2 |

1680*940*1050 |

1380 |

| US-10B Totally-Enclosed |

4 |

40 |

62 |

160-180 |

30*55 |

15 |

25 |

25 |

|

2.2 |

1680*940*1050 |

1400 |

| US-10G Semi-Closed |

4 |

40 |

72 |

180-220 |

30*60 |

15*36 |

25*55 |

25*60 |

|

2.2 |

1680*940*1050 |

1500 |

| US-15 Semi-Closed |

5 |

50 |

81 |

140-160 |

34.5*67 |

19 |

31 |

31 |

|

3 |

2100*1100*1200 |

1800 |

| US-15 Totally-Enclosed |

5 |

50 |

81 |

140-160 |

34.5*67 |

19 |

31 |

31 |

|

3 |

2100*1100*1200 |

1850 |

| Model | Max.Cutdiameter | Max.BlankLengt | Stroke | Output rate | MainDie Diameter | Cut-offDie Dia | PunchDie (1st) | PunchDie (2nd) | Size of scissors plate | Body Motor Power | L*W*H | Weight |

| US-15A Half-Hollow |

5 |

70 |

102 |

70-100 |

34.5*100 |

19 |

31 |

31 |

|

3 |

2400*950*1150 |

1950 |

| US-15B Semi-Closed |

5 |

63 |

102 |

140-160 |

34.5*80.5 |

19*45 |

31*80 |

31*90 |

|

3 |

2080*1060*1120 |

1850 |

| US-15B Totally-Enclosed |

5 |

63 |

102 |

140-160 |

34.5*80.5 |

19*45 |

31*80 |

31*90 |

|

3 |

2080*1060*1120 |

1900 |

| US-15G Totally-Enclosed |

5 |

75 |

115 |

140-160 |

34.5*100.5 |

19*45 |

31*85 |

31*95 |

|

4 |

2210*1090*1190 |

2200 |

| US-15G Semi-Closed |

5 |

75 |

115 |

140-160 |

34.5*100.5 |

19*45 |

31*85 |

31*95 |

|

4 |

2100*1090*1150 |

1800 |

| US-20 Totally-Enclosed |

6 |

75 |

124 |

100 |

45 |

25 |

36 |

36 |

|

4kw-Level 6 |

2800*1150*1270 |

2600 |

| US-20A Half-Hollow |

6 |

70 |

136 |

100 |

45 |

25 |

36 |

36 |

|

4kw-Level 6 |

3020*1050*1215 |

2850 |

| US-20B Semi-Closed |

6 |

100 |

136 |

90 |

45*120 |

25*55 |

36*80 |

36*90 |

80*40*11 |

4kw-Level 6 |

2400*1180*1300 |

2850 |

| US-20B Totally-Enclosed |

6 |

100 |

136 |

90 |

45*120 |

25*55 |

36*80 |

36*90 |

80*40*11 |

4kw-Level 6 |

2565*1275*1505 |

2950 |

| US-24B Semi-Closed |

7 |

120 |

170 |

80 |

48 |

25 |

38 |

38 |

|

5.5kw-Level 6 |

3270*1200*1340

|

3500 |

| US-24B Totally-Enclosed |

7 |

120 |

170 |

80 |

48 |

25 |

38 |

38 |

|

5.5kw-Level 6 |

3270*1200*1580 |

3850 |

| US-25 Semi-Closed |

9 |

150 |

220 |

60 |

55 |

28 |

38 |

38 |

|

7.5kw-Level 6 |

4000*1450*1500 |

6800 |

| US-25 Totally-Enclosed |

9 |

150 |

220 |

60 |

55 |

28 |

38 |

38 |

|

7.5kw-Level 6 |

4000*1450*1550

|

7000 |

| Model | Max.Cutdiameter | Max.BlankLengt | Stroke | Output rate | MainDie Diameter | Cut-offDie Dia | PunchDie (1st) | PunchDie (2nd) | Size of scissors plate | Body Motor Power | L*W*H | Weight |

| US-25A Half-Hollow |

9 |

150 |

220 |

60 |

55 |

28 |

38 |

38 |

|

7.5kw-Level 6 |

4000*1950*1600 |

6900 |

| US-30General Cover |

11 |

150 |

220 |

60 |

65 |

35 |

48 |

48 |

|

Level 615kw |

4550*1650*1540 |

8000 |

| US-30 Semi-Closed |

11 |

150 |

220 |

60 |

65 |

35 |

48 |

48 |

|

Level 615kw |

4550*1650*1540 |

8200 |

| US-30 Totally-Enclosed |

11 |

150 |

220 |

60 |

65 |

35 |

48 |

48 |

|

Level 615kw |

4550*1650*1540 |

8350 |

| DSH-15 Two Die Four Punch |

6 |

35 |

70 |

60 |

46 |

19 |

31 |

31 |

|

4 |

2260*1230*1260 |

2500 |

| DSH-20 Two Die Four Punch |

7 |

50 |

90 |

50 |

50 |

28 |

31 |

31 |

|

7.5 |

3230*1480*1520 |

5000 |

| Model | CUT-OFFDIA.MAX. | Max.BlankLength | Ram Stroke | RPM | Main Die | Punch | Motor | L*W*H |

| unit | mm | mm | mm | pcs/min | mm | mm | KW | mm |

|

Z12-6X250 |

8 | 250 | 320 | 30 | Φ50*290 | Φ35*140 | 5.5 | 3700*1500*1700 |

|

Z12-8X300 |

10 | 300 | 380 | 25 | Φ60*350 | Φ40*150 | 7.5 | 4700*1650*1800 |

Semi-Closed

Totally-Enclosed

Self Drilling Screw Heading Machine Final product