- Coil nail machine

- Magnetic feeder

- Nailer

- Nail making machine

- paper collator

- Plastic strip nail making machine

- Bar thread rolling machine

- Staple

- Staple making machine

- Clip nail making machine

- Steel bar straightening cutting machine

- Wire mesh

- Wire Mesh Machine

- Nail

- Wire drawing machine

- Wood Sawdust Blocks Production Line

- Other machines

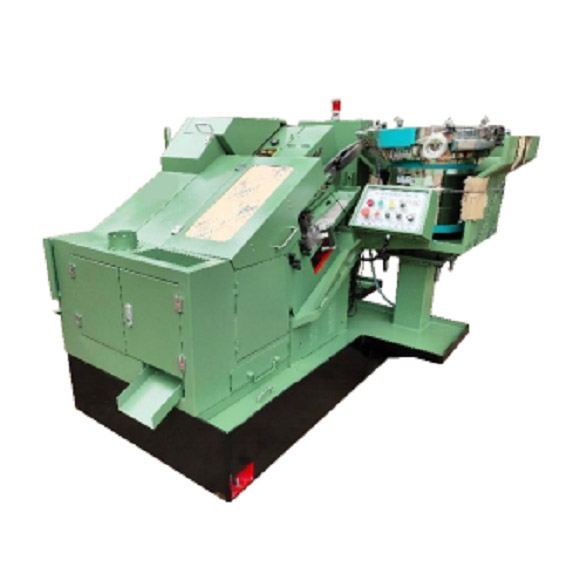

Self drilling screw machine production line

-

Self Drilling Screw Heading Machine

Screw heading machine is a kind of cold heading equipment for producing screws, which is mainly a metal processing machine for basic screw forming. Strong flexibility and convenient length adjustment are suitable for small batch production or proofing. Yield and quality are directly related to operators. Screw forming There are two types of screw shape forming and thread forming: the equipment used for shape forming is a heading machine, which adopts cold heading processing and forming; the equipment used for thread forming is a tooth rolling machine, which adopts extrusion processing and forming. It has better surface quality and higher dimensional accuracy. Due to the cold work hardening in the upsetting process, the amount of deformation should not be too large reduce cracking

-

Self Drilling Screw Thread Rolling Machine

Efficient Forming: The screw thread rolling machine significantly reduces production cost by direct pressing method without cutting process and producing no waste. The high productivity of the machine ensures uniformity of thread finish and accuracy.

Enhanced Strength: Compared with traditional cutting process, thread rolling process produces threads with higher strength and more durable finished products, which are suitable for a variety of industrial applications.

-

Self Drilling Screw Point Forming Machine

The tail of the drill tail screw is in the shape of a drill tail or a pointed tail. It does not need to drill holes on the workpiece first, and can directly drill, tap, and lock on the setting material and base material. Compared with ordinary screws, the drill tail screw High tenacity and retention force, it will not loose after a long time of combination, easy and safe to use, drilling and tapping can be completed in one operation, saving time, labor and labor. Drilling screws are mainly used to fix metal plates such as steel plate fasteners, generally used for locking metal plates and non-metallic plates, such as for directly fixing silicon-calcium boards, gypsum boards and various wood boards on metal plates. Drilling screws with reasonable design and structure can make the metal plate and the mating plate tightly locked, avoiding damage and scratches of the mating plate, and are easy to install.