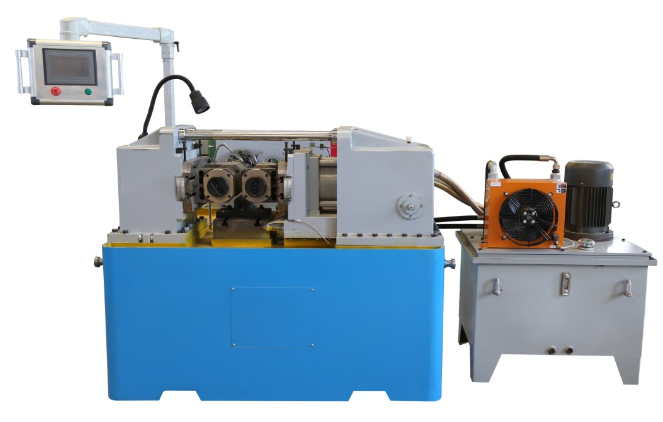

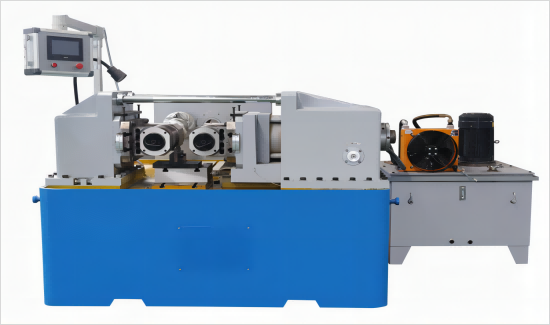

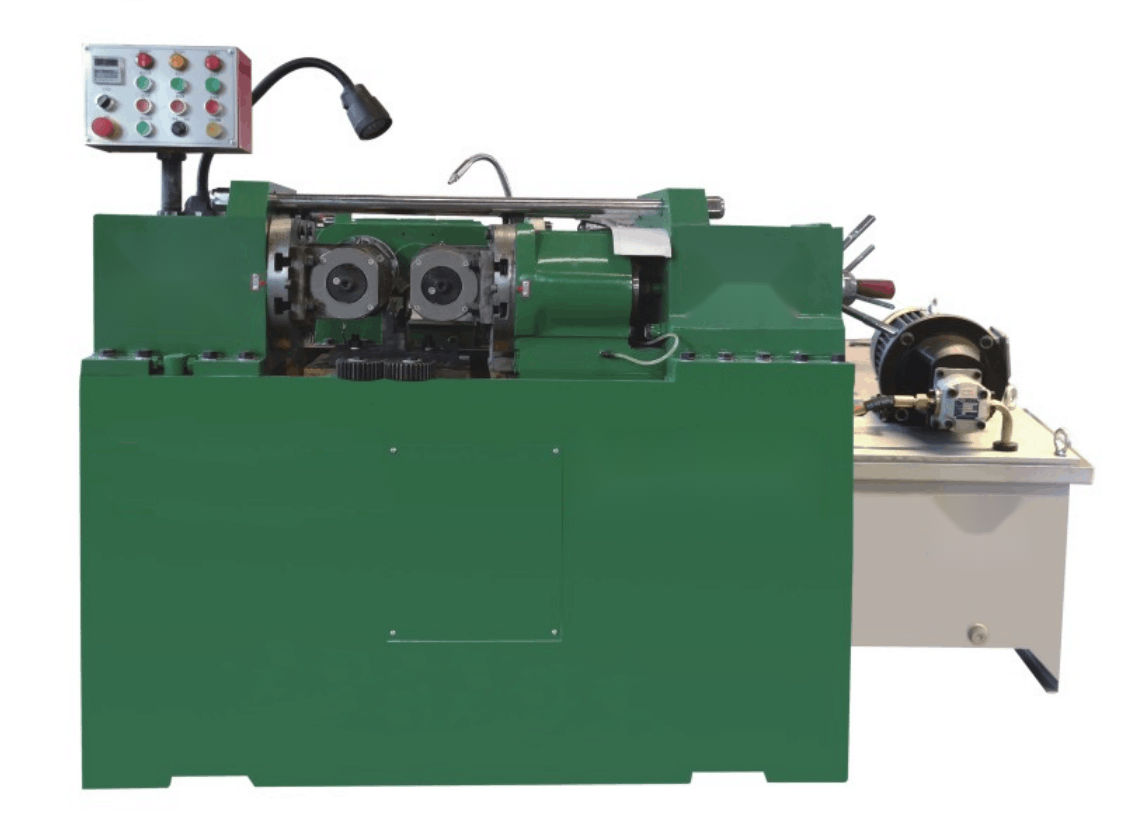

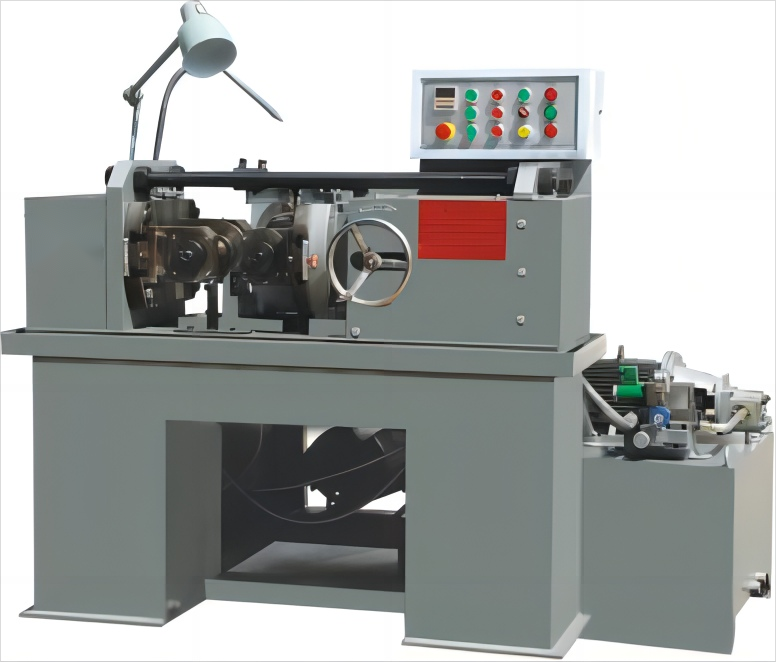

Thread Rolling Machine Model Z28-260

Detais

Equipment features

Versatile thread processing: High-precision stamping of common threads, rapezoid thread and modular threads to meet a variety of production requirements.

Wide material applicability: it can process imperial carbon steel, inert steel and non-ferrous metals with elongation greater than 10% and tensile strength less than 1000NV/mm², adapting to a wide range of material types.

Efficient production: The machine can be equipped with automatic feeding device according to the user's needs, which further improves the production efficiency and reduces human intervention.

This high performance external threading press is an ideal choice for the production of precision standard parts due to its wide range of threading capabilities and material suitability. Equipped with automatic feeding device, it can significantly improve the production efficiency and meet the various needs of users.

specification

|

Pressure of Roller max |

260KN |

Dip Angle of Min Shaft |

土10° |

|

Working Dia |

Axial 65mm Radial 90mm |

Rotary Speed of Main Shaft |

20.32.53.86 ( r/min ) |

|

Thread Distance max |

Axial 6mm Radial 8mm |

Rolling Power |

11 kw |

|

Roller Dia max |

Φ220mm |

Hydraulic Power |

5.5kw |

|

BD of Roller |

Φ75mm |

Cooling Power |

90w |

|

Roller Width max |

160mm |

Weight |

3500kg |

|

Center Distance of Main shaft |

180-300mm |

Size |

1800x1950x 1 800mm |