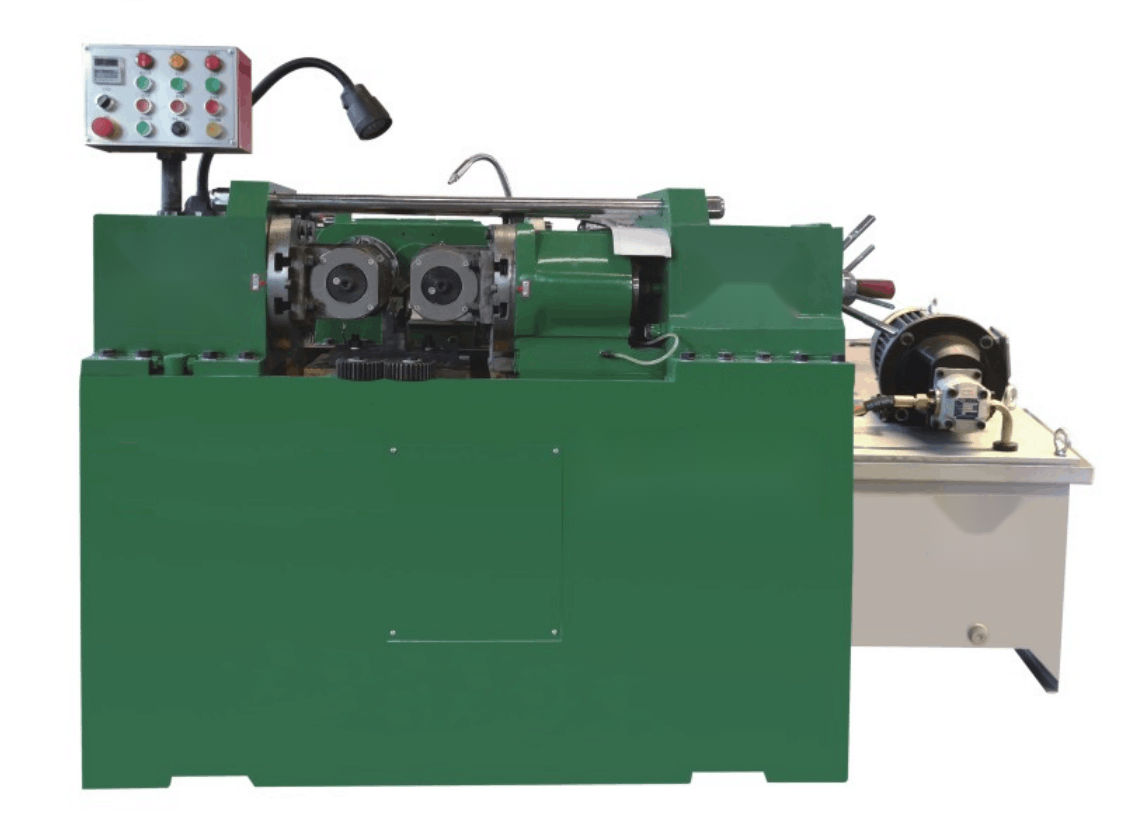

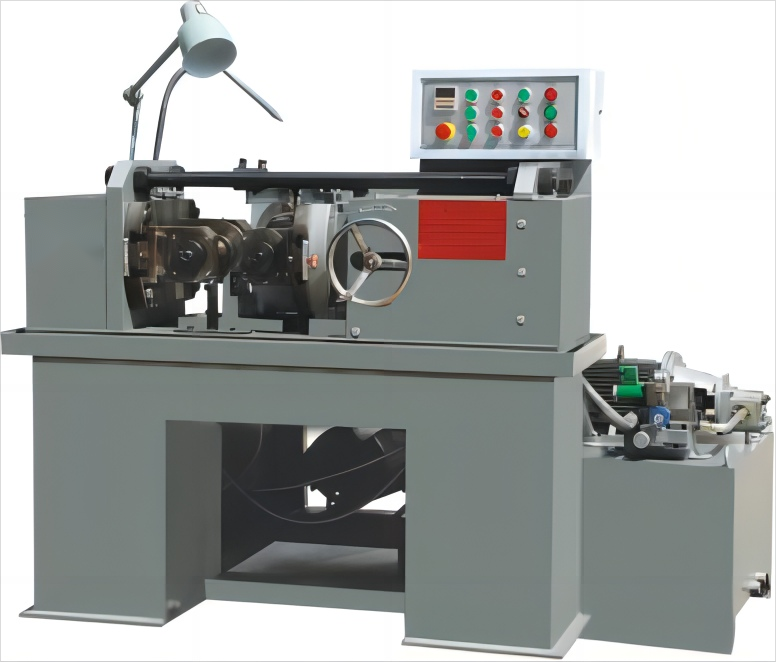

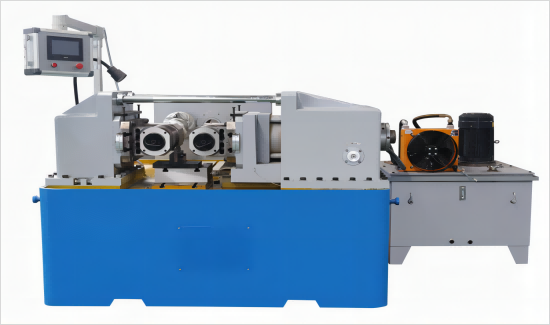

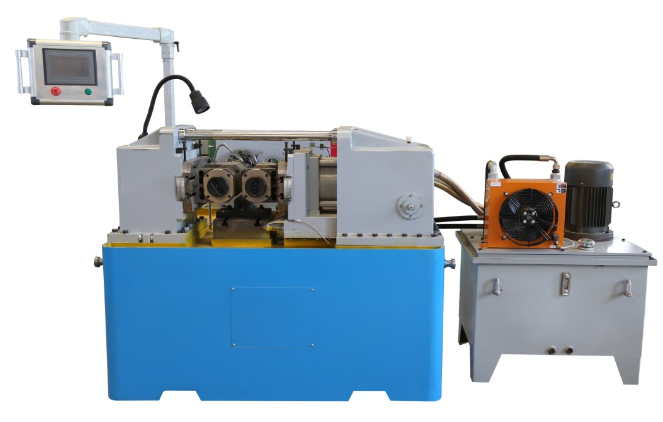

Three-axis thread rolling machine Z28-16

Details

Equipment Features

Component consistency: The machine is mainly composed of three identical thread rolling shaft assemblies and sliding sleeve cylinder hydraulic system, which ensures the stability and reliability of the machine.

Synchronised movement: The machine body supports three identical cylinders, and the bottom of the cylinders support three identical thread rolling shaft assemblies, which achieve synchronised in-and-out linear movement, thus completing the workpiece clamping, cutting and releasing retraction process.

Efficient machining: The transmission and gear shift mechanism enables the three output thread rolling shafts of the drive shaft to rotate in the same direction and at the same speed, enabling the thread rolling process to be completed efficiently and with increased machining efficiency.

Comprehensive system: In addition to the thread rolling shaft assembly and the hydraulic system, it also includes the transmission mechanism, the gear shift mechanism, the electrical system and the cooling system, which builds up a complete machining system and ensures the stable operation of the machine and the quality of the workpieces processed.

Versatility: The machine can not only process regular threads, but also irregular threads and through-screws, with strong applicability and flexibility.

specification

| Maximum rolling pressure | 160KN |

| Rolling diameter | Φ25-Φ80MM |

| Maximum rolling pitch | 6MM |

| Rolling wheel diameter | Φ130-Φ160MM |

| Rolling wheel aperture | Φ54MM |

| Rolling wheel maximum width | 80MM |

| Spindle tilt angle | ±5° |

| Rolling power | 11KW |

| Hydraulic power | 2.2KW |

| Cooling power | 90W |

| Machine quality | 1900KGS |

| Dimensions | 1400*1160*1500MM |