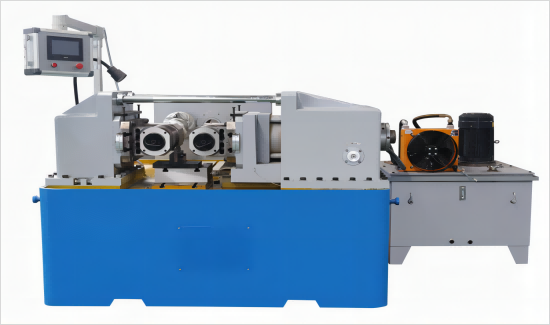

UST 4-10 NC Steel Bar Straightening Cutting Machine

1. Straightening and cutting steel bar dia: ¢8-¢10mm

2. Cutting length: 0.75m-6m3. speed: 50m/min

3. Output (each 8hours): ¢6(4-5tons); ¢8(6-8tons); ¢10(8-10tons)

4. Input batches simultaneously: 1-20batches

5. Single batch cut pieces: 1-9999. Length tolerance: ±3-4mm

6. Power: 50HZ

7. CNC box power: ≤14w

8. Volume: 2500×700×1300mm

Main used to cut round bar straightening and cutting.

|

Straightening wire dia |

Φ8mm-φ10mm |

|

Automatic cut off |

0.75-6m |

|

Cut off length tolerance |

±3-4mm |

|

Straightening speed |

50m/min |

|

Straightening barrel motor power |

7.5KW |

|

Hydraulic cut off motor power |

4KW |

|

Servo motor |

2KW |

|

weight |

900KG |

Main machine

Traction CNC meter device

Control panel

2.5tons finished wire device

For the usage of the machine, we can say:

For straightened steel, you should always pay attention to the working conditions of the coil rack. When you find confusion, you should stop the machine immediately. After the coil processing is completed, you should take out the tail material from the coil rack. After the processing is finished, the switching power supply should be turned off immediately. The application range of the cutting machine is getting wider and wider. It is used in many large-scale projects, which brings great convenience to construction projects and saves a lot of labor.