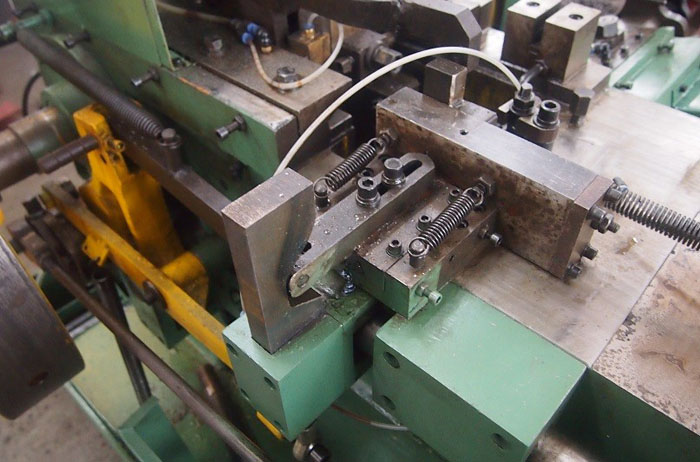

Z12 Series 1-Die 2-Blow Cold Heading Machine

1. The machine main frame and ram etc have been heat treated for releasing the internal stress and normalized after casting to avoid any deformation in long term operation and keep a stable precision.

2. Cut-off roller is supported on both sides to gain maximum rigidity and stable cut-off.

3. A simple and rational design for absorbing the up and down moving shock of punch slider with a quick adjustment and easy maintenance.

4. Overam type main slider with liners made of high alloy steel allows long and stable precision. The P.K.O. prevent spill-out of the forged parts from forming die before being knock out.

5. Safety pins are used for knock out and cut-off mechanism to prevent any damage of the machine parts.

6."Inching", "Single Stroke" and "Continuous Running" makes alignment of machine with tooling much easy.

7. A PLC controlled safety checking system can monitor the performance of key system and display and alarm any abnormality.

|

Model |

Maximum diameter |

Maximum length |

Ram Stroke |

Out put Rate |

Main Mould |

Cut-off Die |

Pnch Die |

Cutter Size |

Mechanical Dimesions |

Main Motor |

Net weight |

|

Z12-3 |

4 |

20 |

40 |

160-190 |

φ20*36 |

φ13*25 |

φ18*50 |

6*25*42 |

1.4*0.75*0.9 |

1.1 |

624 |

|

Z12-4 |

5 |

40 |

60 |

140-170 |

φ32*60 |

φ15*30 |

φ25*65/70 |

10*35*72 |

1.8*0.85*1.5 |

2.2 |

1274 |

|

Z12-5 |

7 |

60 |

90 |

110-140 |

φ32*80 |

φ20*35 |

φ30*75 |

10*35*72 |

2.3*1.08*1.25 |

3 |

2080 |

|

80 |

110 |

90-110 |

φ32*100 |

φ20*35 |

φ30*80 |

10*35*72 |

2.4*1.15*1.35 |

2145 |

|||

|

100 |

130 |

80-100 |

φ35*120 |

φ20*35 |

φ30*80 |

10*35*72 |

2.5*1.15*1.35 |

2210 |

|||

|

150 |

190 |

80-100 |

φ40*180 |

φ20*35 |

φ35*100 |

10*35*72 |

2.6*1.15*1.35 |

2990 |

|||

|

Z12-6 |

9 |

90 |

120 |

80-100 |

φ50*120 |

φ24*40 |

φ35*100 |

12*35*77 |

2.7*1.4*1.6 |

5.5 |

3380 |

|

120 |

150 |

70-90 |

φ50*150 |

φ24*40 |

φ35*100 |

12*35*77 |

2.8*1.4*1.6 |

3640 |

|||

|

150 |

190 |

60-70 |

φ50*180 |

φ24*40 |

φ35*100 |

12*35*77 |

3.0*1.4*1.6 |

4160 |

|||

|

170 |

230 |

50-60 |

φ50*220 |

φ24*55 |

φ35*120 |

12*35*77 |

3.2*1.4*1.6 |

4360 |

|||

|

200 |

250 |

40-50 |

φ50*240 |

φ24*55 |

φ35*120 |

12*35*77 |

3.65*1.4*1.65 |

4940 |

|||

|

250 |

290 |

30-45 |

φ50*290 |

φ24*60 |

φ35*140 |

12*35*77 |

3.7*1.5*1.7 |

5460 |

|||

|

Z12-8 |

11 |

120 |

160 |

60-80 |

φ60*160 |

φ28*45 |

φ40*120 |

12*42*90 |

3.75*1.6*1.8 |

7.5 |

4940 |

|

150 |

190 |

60-70 |

φ60*190 |

φ28*45 |

φ40*120 |

12*42*90 |

3.9*1.6*1.8 |

6240 |

|||

|

200 |

250 |

40-50 |

φ60*240 |

φ28*60 |

φ40*150 |

12*42*90 |

4.15*1.6*1.85 |

6500 |

|||

|

250 |

290 |

30-45 |

φ60*290 |

φ28*60 |

φ40*150 |

12*42*90 |

4.3*1.6*1.9 |

7800 |

|||

|

Z12-10 |

13 |

120 |

160 |

50-60 |

φ80*160 |

φ35*50 |

φ50*150 |

16*55*115 |

4.8*1.8*1.32 |

11 |

8450 |

|

180 |

230 |

50-60 |

φ80*220 |

φ35*50 |

φ50*150 |

16*55*115 |

4.8*1.8*1.32 |

8650 |

|||

|

220 |

270 |

40-50 |

φ80*260 |

φ35*50 |

φ50*150 |

16*55*115 |

5.0*1.8*1.32 |

9100 |

|||

|

Z12-12 |

15 |

150 |

190 |

40-50 |

φ88*200 |

φ45*60 |

φ60*180 |

18*60*125 |

5.2*1.9*1.8 |

18.5 |

14040 |

|

200 |

250 |

30-40 |

φ88*260 |

φ45*60 |

φ60*180 |

18*60*125 |

5.2*1.9*1.8 |

14300 |

|||

|

280 |

330 |

30-40 |

φ88*340 |

φ45*60 |

φ60*180 |

18*60*125 |

5.2*1.9*1.8 |

15600 |

|||

|

300 |

350 |

25-35 |

φ88*360 |

φ45*60 |

φ60*180 |

18*60*125 |

5.2*1.9*1.8 |

15860 |